An Industrial Chiller is a must-know for anyone looking to work in the manufacturing industry. To regulate the temperature of the working environment, equipment, or other requirements. Here is some fundamental information

An industrial chiller is a refrigeration system that cools process fluids, machinery, or air in industries. They are essential for maintaining precise and controlled temperatures, which is crucial for various industrial applications. Chillers transfer heat away from a space that requires climate control much like a traditional split system or package unit does, but they use water (or a water solution) to do so instead of air. There are two types of chillers: water-cooled and air-cooled. They work similarly throughout most of the process until the refrigerant reaches the condenser.

Applications of industrial chillers:

# Manufacturing: Injection molding, plastic extrusion, metalworking.

# Food and beverage: Processing, storage, and transportation.

# Pharmaceutical: Production and storage of drugs.

# Data centers: Cooling servers and other equipment.

How does Chiller work:

Industrial chillers typically work on the principle of vapor compression or vapor absorption. In the vapor compression cycle, a refrigerant is circulated through the system, absorbing heat from the process or environment and releasing it outside. In the vapor absorption cycle, heat energy is used to drive the refrigeration process.

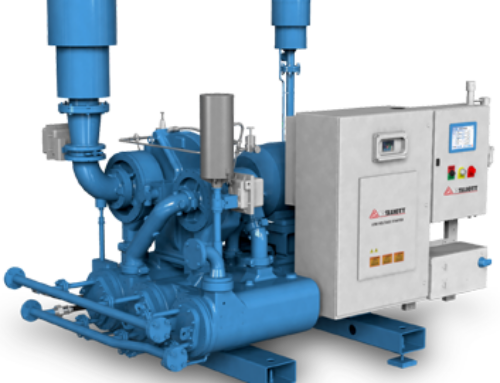

Key Components of an industrial chiller:

# Evaporator: Absorbs heat from the process fluid or air.

# Compressor: Increases the pressure of the refrigerant.

# Condenser: Releases heat from the refrigerant to the environment.

# Expansion valve: Reduces the pressure of the refrigerant, causing it to evaporate and absorb heat again.

Types of Industrial Chillers:

# Air-cooled chillers: Dissipate heat to the ambient air.

# Water-cooled chillers: Use water as a cooling medium.

# Evaporative chillers: Combine air and water cooling for efficient heat rejection.

Benefits of Using Chillers:

# Temperature Control: Maintains precise temperature levels for optimal performance.

# Energy Efficiency: Can be designed to optimize energy consumption.

# Reliability: Provides consistent cooling performance.

# Versatility: Can be used in various applications and industries.

By understanding the basic principles and applications of chillers, you can appreciate their significance in modern technology and industry.

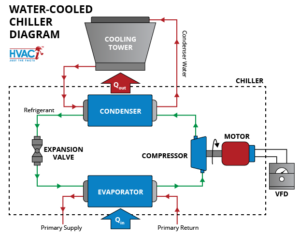

The cooling process begins when water enters the evaporator from the primary return where heat is transferred from the water to the refrigerant.

The now-chilled water is then sent to the water tank via the primary supply (shown in blue), where it is distributed to the various climate-controlled spaces by the water pump. Because heat always moves from hot to cold as stated by the second law of thermodynamics, the chilled water absorbs the conditioned space’s ambient heat in the air handler. A fan then forces the cooled air into the space via the ductwork. The warmer water is then returned to the chiller to be cooled once again.

In the meantime, the heat absorbed by the refrigerant (path shown in green) in the evaporator needs to be transferred to allow the refrigerant to absorb more heat. The low-pressure, high-temperature refrigerant moves from the evaporator to the motor-run compressor, which increases the pressure and temperature.

After that, the refrigerant enters the condenser. Water-cooled chillers use water to surround the refrigerant pipes and draw in the heat (path shown in red). The water is then pumped into a cooling tower to release the heat. After condensing, the refrigerant goes through an expansion valve to reduce pressure (and temperature) before returning to the evaporator, where the process begins again.

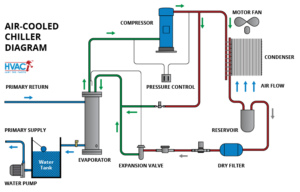

Like with water-cooled chillers, the process begins with the primary return bringing warm water to the chiller. Heat is transferred from the evaporator to the refrigerant, and the water runs through the primary supply to the cooled space. The refrigerant moves through the compressor to raise the pressure and temperature, and then it reaches the condenser. Here, fans circulate outside air through the condenser, which absorbs heat from the refrigerant (again, the second law of thermodynamics dictates that hot moves to cold) before expelling this heat to the ambient air. The refrigerant then goes through the expansion valve (as before) and returns to the evaporator.

Leave A Comment